Mounting Systems -- A pictorial Guide

Mount Types

- Ground mount

- Pole mount (tracking and fixed)

- Roof mount

- Ballasted mount

- Building Integrated System

Fixed Top of Pole mount:

The top picture is of a stationary pole mounted system in a solar farm at Galletta ON. This a 23.4MW solar farm south east of the town Arnprior, Ontario, Canada. It consists of 312,000 PV thin film solar panels made by First Solar mounted on 13,000 racks on a 200 acre field. Each rack has two posts and holds 24 solar panels (4 rows of 6.) The posts were augered into the ground. These are 70W, Cadmium Telluride cell based panels, unusual as most panels are made with silicon solar cells. They have a module efficiency of 10.5%, a little lower than mono or poly-silicon call based panels. This approach is attractive when you have a large amount of space to mount panels.

The video shows a television news clip about the system. Note that this system is fixed, and ask yourself why they did not use a tracking mount. One could conclude that the return on investment is better with a lower cost, lower complexity mount.

This represents a basic top of pole mounted system. One pole set in concrete, with a manual tilt adjustment. This is about a 0.5 kWh system. The four black boxes hold the bypass diodes, and provide a wiring attachment site to bond flexible wires to the solder strips of the panel's cells. An astute observer will not that currently this is not connected to an inverter. The mounting pipe is a 3" well casing pipe.

Side of Pole Mounting

Although they are not common for microFIT applications, side of pole mounts are used for small off-grid applications where one to two panels are mounted on the side of one pole.

Tracking Pole mount:

This is a 10kWH dual axis tracking mount. The East-West drive is inside the red ring, and the north south is a worm drive linear actuator seen in front of the top of the mounting pole. This is the high end type of mount, acheiving about 30% more energy production than from a similar sized fixed mount system. It tips vertical once per day first thing in the morning during the winter, to dump of any snow. At night it parks to minimize its exposure to the wind. During the day it tracks the predicted path of the sun, and does not track the brightest object in the sky. This is the SGT-10500 Dual Axis Tracker made in Ontario by by Sentinel Solar. Click here for more information on tracking mounts.

Ballasted mount:

Here is an example of the back side of a ballasted mount, that would normally be mounted on the ground or on a flat roof. The back cover would be removed, and something heavy such as sandbags or concrete blocks would keep the mount in place. This particlar example is at a training site, and is mounted onto a wood platform instead. The purpose of the rear cover is to reduce the risk of the wind picking up the mount. Some mounting frames are even simpler, and do not have a back cover.

When this type of mount is installed at ground level, there will be a tendency for rain to splash dirt onto the tempered glass front of the Photovoltaic panels, and reduce the amount of light reaching the cells in the panel. This would require more frequent cleaning than all other types of mount.

On a gravel flat roof of a commercial building, some of the same contamination of the glass surface should be expected, and regular cleaning will enhance output.

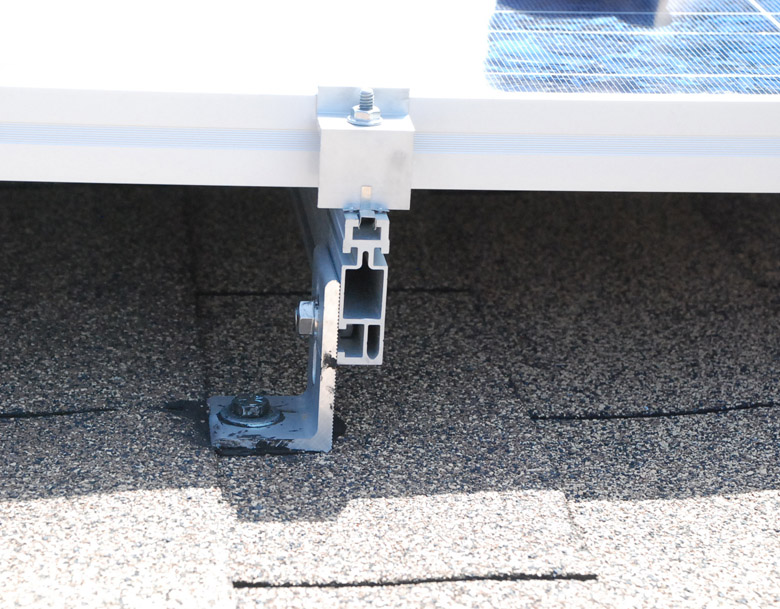

Roof Mounted

This is a small scale example of a system mounted on a conventional roof, with ashphalt shingles. The box at the top right is a combiner box, where the wires from the individual panels leave the roof and are wired to a cable connecting to the bulk inverter. This is mounted using a rail system made by Unirac, and uses SolGate panels. Both of these components qualify as Ontario content.

This is usually the lowest cost mounting system for the average homeowner if: the roof is in good shape and the shingles will last at least 20 years, and the slope is suitable. The slope on this roof is less than the 30 to 45 degree range that is best for the Ottawa Valley region.

Click here for a series of annotated photographs of the installation of this system.

Building Integrated Panel

This is a house where the glass surface of the Photovoltaic panel also forms part of the building's waterproof exterior. The 8 panels are visible in the forefront, below the closer set of windows. This is an expensive way to install solar electric generation. It may have some architectural advantages, but it has some cons as well.

The panels run hot, as they have no air flow over the back of the panels to provide cooling. This extra heating reduces the amount of electricty produced for a fixed amount of light. The cooler the cells, the more efficiently they operate. This is a high cost mounting method which is not attractive to retrofit to and existing builing, and thus is not attractive as a investment based system. You can see by the sun that I took this early in the morning, as the building is facing due south. due to the dormer windows this roof would not be a good mounting site for panels on the left of the dormer, as it would be in the shade. Typically dormers and solar panels don't mix well on the same roof!

A recent product is a different approach to a BIP, where the solar panels lock together and form the roofing surface, and so offer a lifetime roof which is also a Photovoltaic array. No racking is required, it installs over Ice & Water shield, directly onto the roof. More details of the product made by SolarShingleCanada is available at www.pvtech.ca This product is comparable in price to a replacement of asphalt shingles and traditional solar panels with rooftop racking.